Enhancing Performance and Durability with Nickel Alloy Round Bars and Forged Fittings

In today’s rapidly evolving industrial landscape, the demand for high-performance materials that can withstand extreme conditions is at an all-time high. Nickel alloys have emerged as a popular choice for various applications due to their exceptional strength, corrosion resistance, and thermal stability. In this blog post, we will explore two essential components in the realm of nickel alloys: nickel alloy round bar and nickel alloy forged fittings. Let’s delve into the properties, applications, and advantages of these remarkable engineering solutions.

Nickel alloy round bars are cylindrical bars crafted from a combination of nickel and other elements such as chromium, molybdenum, and iron. These alloys possess outstanding mechanical properties, making them suitable for a wide range of industries, including aerospace, oil and gas, chemical processing, and marine engineering.

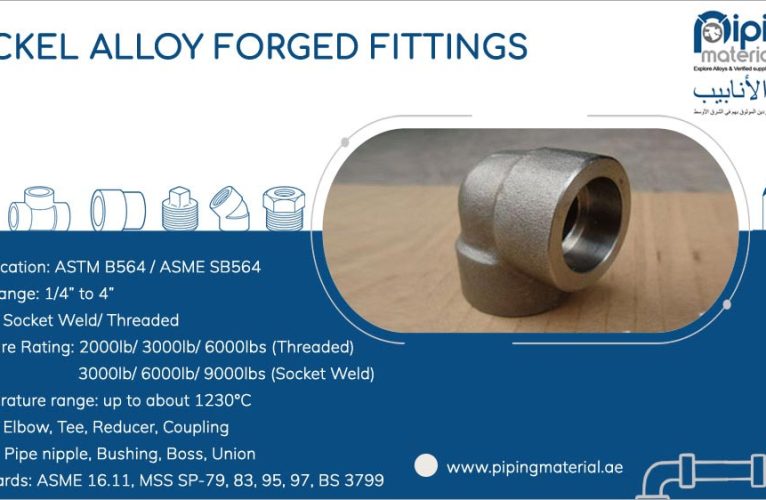

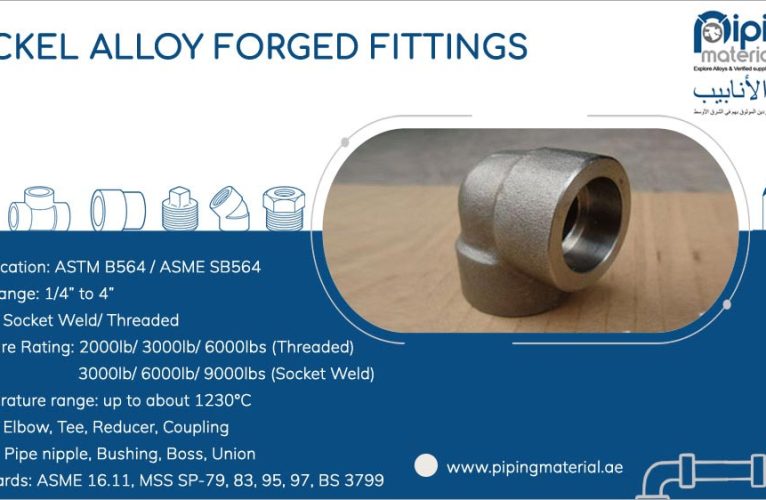

Nickel alloy forged fittings, also known as nickel alloy pipe fittings, play a crucial role in connecting pipes, valves, and other equipment in industrial systems. These fittings are created through a forging process that involves heating the material and shaping it into the desired form. Here are some notable advantages of nickel alloy forged fittings:

Nickel alloy round bars and nickel alloy forged fittings are essential components in industries that demand exceptional performance, durability, and reliability. These materials offer outstanding corrosion resistance, high strength, and thermal stability, making them well-suited for challenging environments and critical applications. Whether it is offshore drilling, chemical processing, power generation, or aerospace engineering, the versatility and properties of nickel alloys contribute to safer and more efficient operations. By leveraging the unique characteristics of nickel alloys, industries can optimize their performance while reducing maintenance and replacement costs, ultimately driving progress and innovation forward.

tags: Nickel alloy round bar

Introduction to Braided Wigs Braided wigs have become a game-changer for many Black women, offering...

In today’s fast-paced world, having a reliable key cutting service nearby is a must. Whether...

Venturing into the world of business ownership can be a daunting task. With numerous decisions...